More softwares at account-plus.net!

Best SCM, Supply Chain Management System in Karachi, Lahore, Islamabad across the Pakistan

|

Main problem of any distribution company is to manage their supply chain effectively and accurately. Accounts Plus provides effective solution to manage network of interconnected business involved in the provision of product and services required by the end customers. Manage entire activity through forecast, planning, purchasing, internal processing of materials into finished goods. Accounts Plus spans all movement and storage of raw materials, work-in-process, inventory and finished goods from pint of origin to point of consumption.

|

| Key Features |

| Multiple Company |

Multiple Location / Branch |

Uniform format of pulling data from distributor systems |

| Real-time data on nationwide stock level |

Adaptive dispatch plan on distributor stock and sales history |

Timely, accurate and automated secondary sales reporting leading to accurate planning |

| EOBI / SESSI |

Income Tax |

Loan Management |

| Monitoring inventories on warehouses and distributor points |

Accurate demand and sales forecasting |

Sales team spending time in business generation instead of compiling manual reports |

| Distributor performance metrics |

Distributor performance against constantly changing sales target |

Sales growth analysis |

| Slow and fast moving products |

Stock Analysis |

Seasonal and geographical sales average |

| Last year vs. current year sales performance |

Target vs. sales |

Geographical/Weekly sales vs. target |

| Geographical vs. overall sales ratio |

Top to bottom sales and ratio |

All reports on value, volume, pcs and carton base |

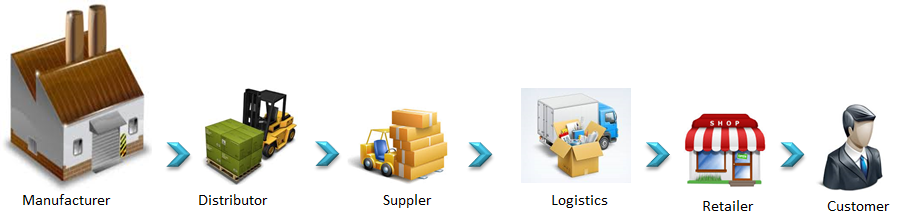

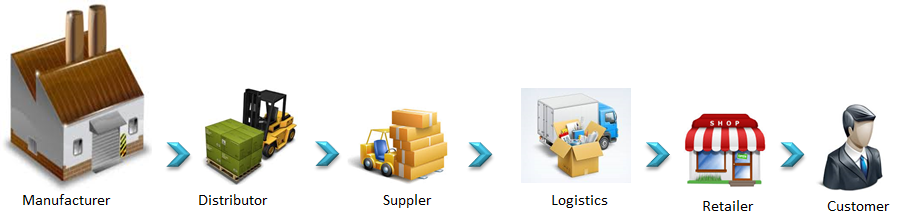

Supply Chain Management

The size of the global supply chain over the years so many companies have grown with each other.

Companies need their supply chains in a way that helps to fulfill them manage their customers' needs.

Many things can go wrong

Fire

Theft

Competition

Government regulations

Supply Chains

All actors in the value chain have its processes and methods they use to ensure delivery. Core product

These players do not understand, to cope with vulnerabilities and the impact they may have on them. It is only after a significant disturbance of the security of the whole system is an important factor.

This has been the shortcomings of the most celebrated supply chain strategies in contact, such as outsourcing.

Other strategies that off shoring and just-in-time inventory management is not limited to failures. Some supply chain practitioners have even blamed this policy if it does not recover from disasters. Responsible for

Supply Chain Risks

Supply chain risk management includes strategies to minimize the adverse effects. On the supply chains

These adverse effects are many actors in the value chain. The network and the complexity of the supply chains require effective risk management strategies.

There are many risk management functions within supply chains:

Inventory

Inventory management, procurement, storage and requires treatment to meet the expectations of the materials.

Customers

Supply chain strategies that minimize off due to lack of raw materials to the potential for interference. These procedures, usually, involve smooth a large inventory buffer.

Such methods of reducing the risk of failure are minimized expensive and unreliable. This is because, in general, leads to an increased load on and operating costs.

Supplier Management

Own, even within the supply chain pressure on suppliers to lower prices, with many suppliers and short delivery times.

Although these approaches seem to work for some time, they are sustainable in the long run. Supplier relationships are tense and toxic. Providers will then lack the motivation to work for the good of the entire company. This is because they feel the treatment they receive unfair it is.

You will then take to compromise in hopes of a better result. A reduction in the quality of products is the inevitable result of these actions. To make matters worse, creating a real crisis in the chain suppliers are not out of their way to help.

Insurance

With any insurance helps a company to get after an error. Back on his feet

The insurance is in helping companies to bounce back from failures significant. But it cannot compensate for certain types of losses, such as the death of a worker.

It is not easy for any business lost after an accident with insured losses.

Emergency Planning

Supply chain risk management to help identify potential risks. Programs these programs have concrete plans to take when problems arise, the measures.

This allows businesses to bounce back from disruptive events in the shortest time and lowest cost on returns.

Contingency planning is about the possible disruptions that may occur. The potential risk of the corresponding series of actions to dictate otherwise.

Contingency involves preparation for predictable and unexpected event and has the following phases:

Recognition of the current situation

Identification of potential risks

Evaluate scenarios

Impact

Risk management strategy

Plan preparation and management responsibilities

Simulation crisis